Intermittent mist systems are widely used to propagate softwood, hardwood and herbaceous cuttings. At time intervals, mist nozzles apply a spray of water that coats the surface of the leaf and medium.

The most important function for this film of water is to intercept the energy from light so that the water on the surface of the leaf evaporates rather than forcing the leaf to evaporate internal water. This prevents the leaf from wilting until roots have formed.

Mist systems can be installed in the greenhouse to root cuttings where the grower wants to more accurately control environment factors, especially temperature and moisture.

Alternatively, softwood cuttings can be rooted in outdoor mist beds. This is the most common method for most landscape shrubs.

The advantage of outdoor mist beds is that they are not as expensive as greenhouse propagation, but it is more difficult to control the environment.

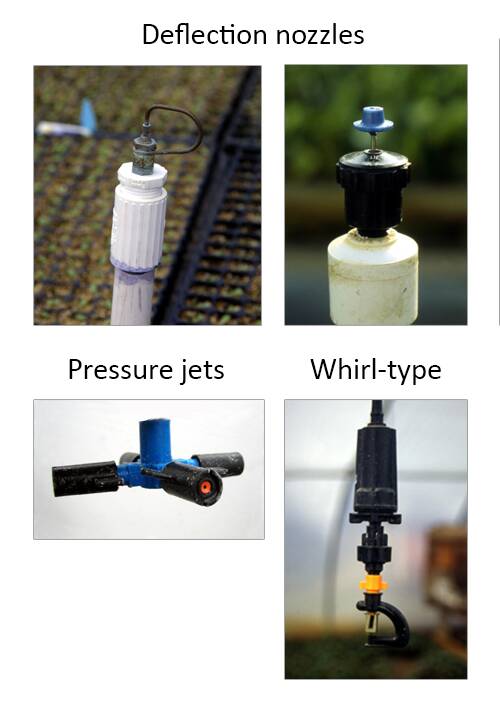

Mist systems use nozzles that have droplets that are greater than 50 microns in size. The two main nozzle types are pressure jets, whirl-type and deflection nozzles. The best pressure jet nozzles, have low water output (<5 gallons per hour) work under low water pressure and do not drip between misting intervals.

Deflection nozzles work by having pressurized water hit against a stop plate that atomizes the water into a mist. The advantage deflection nozzles is that the orifice size is larger than pressure jets and this can reduce clogging.

Intermittent mist systems generally provide a mist duration of 5 to 10 seconds and an interval between misting events of 5 to 20 minutes.

This has been traditionally controlled by a time clock, but there are also systems that are controlled by computers or by machines that mimic leaf evaporation.

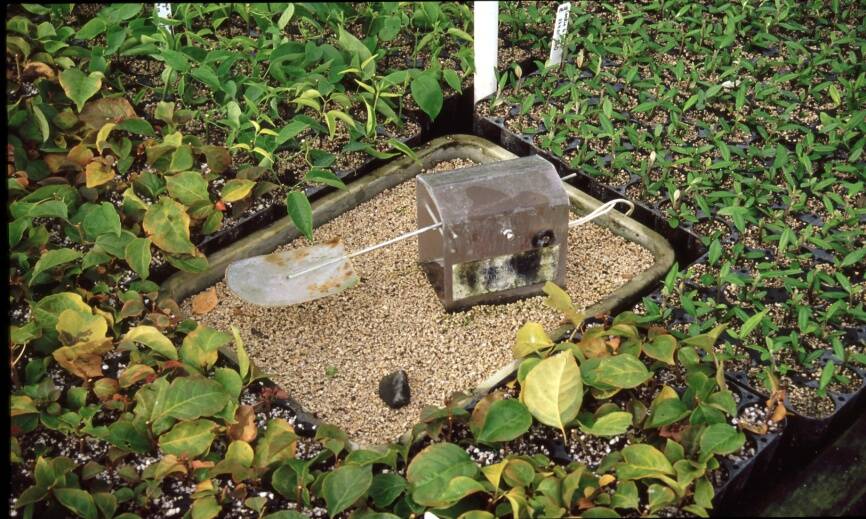

A leaf balance screen is not common but does a reasonably good job of simulating water evaporation from cuttings. As water evaporates from the screen, it moves on a fulcrum triggering the mist.

Regardless of the mechanism used to control mist duration and interval, the controller signals a solenoid that turns on the mist system.

The solenoid is an electronic device that opens a valve when signaled by the controller to allow pressurized water to move to the mist nozzle.

Boom systems offer an alternative to stationary mist systems. Pressurized mist nozzles are located on a traveling boom. The basic boom system does not alter the mechanism for providing a film of water on the leaf surface to prevent wilting in the cuttings.

Rather than having many mist nozzles fixed throughout the greenhouse or field bed, a boom system travels along the bed misting cuttings according to signals from a computer or electronic controller.