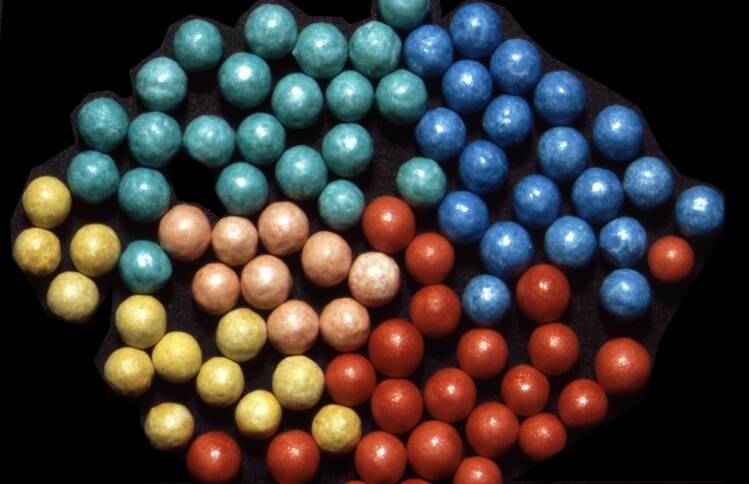

Seeds are pelletized in order to create a uniform, round seed that is easy to mechanically sow.

Many ornamental flower seeds are commonly pelletized for precision sowing one seed per cell in a plug flat.

Pelletized seeds are tumbled in a pan while inert powders like diatomaceous earth and binders form around the seed to provide a uniform shape.

Pelleting adds 25 – 100% increase in size.

Encrusted pellets add <10% increase in size.

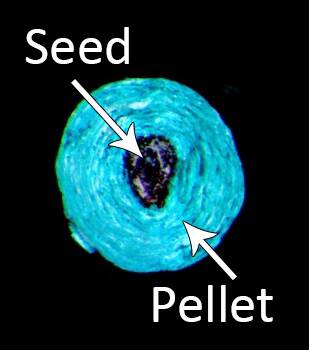

There are two types of pellets distinguished by either "splitting" or "melting" when the coating is wetted.

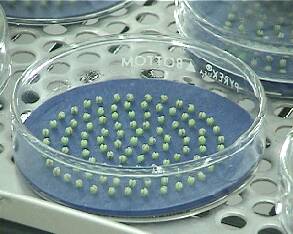

Pelleted petunia seeds with a melting coating.

Example of a split-coat seed pellet.

The coating material is slowly added, while the seeds tumble in the pelleting machine.

This adds size and a uniform round shape to the seeds.

Click on the button below to see video of pelleted seed.